Improving Coal Processing Efficiency with KQT-C Dry-Process Mineral Separation Jig

The coal industry, a significant player in global energy production, is facing increasing pressures to adapt to more efficient, cost-effective, and sustainable practices. Traditional coal processing methods, particularly those relying on water-intensive wet separation techniques, are becoming less viable due to rising operational costs and stringent environmental regulations. In response to these challenges, dry-process mineral separation technologies, such as the KQT-C Dry-Process Mineral Separation Jig, are gaining popularity. These technologies offer a promising solution to improve processing efficiency while reducing environmental impact.

Industry Background and Market Demand

The global coal mining industry has long relied on wet separation techniques to improve the purity of coal by removing impurities such as ash, sulfur, and other non-combustible materials. However, with water becoming an increasingly scarce resource, particularly in regions facing environmental constraints, the need for sustainable and water-efficient technologies has become critical. Additionally, the rising costs of water treatment and disposal of wastewater further highlight the limitations of traditional wet processing methods.

In this context, dry-process mineral separation has emerged as a game-changer. Technologies like the KQT-C Dry-Process Mineral Separation Jig address the growing demand for efficiency, cost-effectiveness, and minimal environmental impact. By eliminating the need for water, dry separation methods help reduce operational costs and water usage while improving coal recovery rates and product quality. As industries move toward more sustainable practices, the adoption of such technologies is expected to increase globally.

Core Concepts and Key Technologies

At the heart of the KQT-C Dry-Process Mineral Separation Jig lies the principle of density-based separation through air pulsation. Unlike wet separation methods that rely on gravity and water flow to separate materials, the KQT-C Jig uses controlled air pulses to create density stratification within the material bed. This allows for the separation of lighter gangue materials from heavier coal particles.

The technology is highly adaptable, allowing operators to adjust air pressure and vibration levels to optimize the separation process based on the feedstock’s characteristics. Heavier particles, such as coal, are directed to the bottom of the bed, while lighter materials, such as ash and sulfur, rise to the top, enabling effective separation with high precision. This dry-process approach not only reduces water consumption but also provides a higher level of control over the separation process, enhancing both efficiency and product quality.

Product Structure, Performance, Materials, and Manufacturing Process

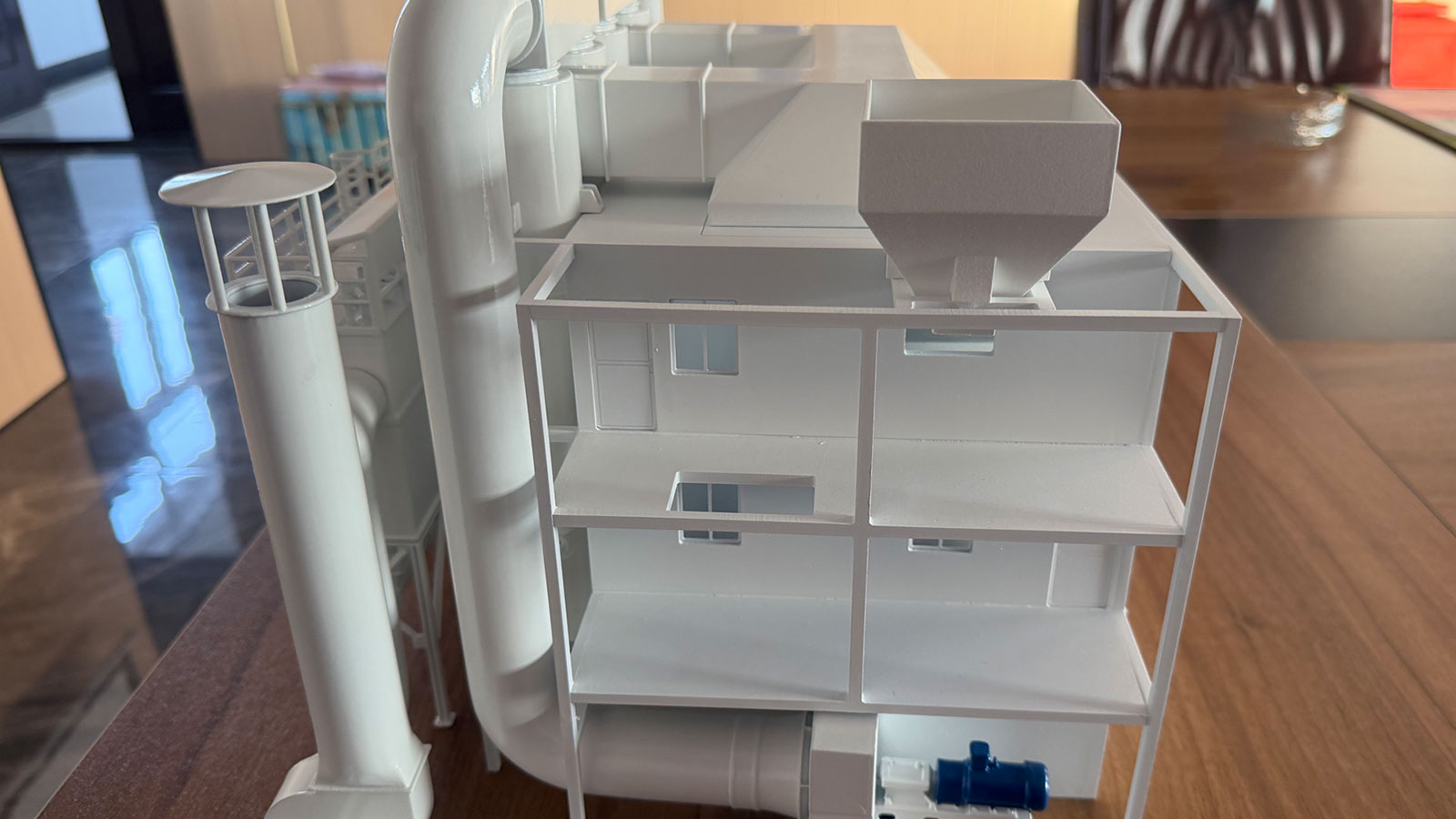

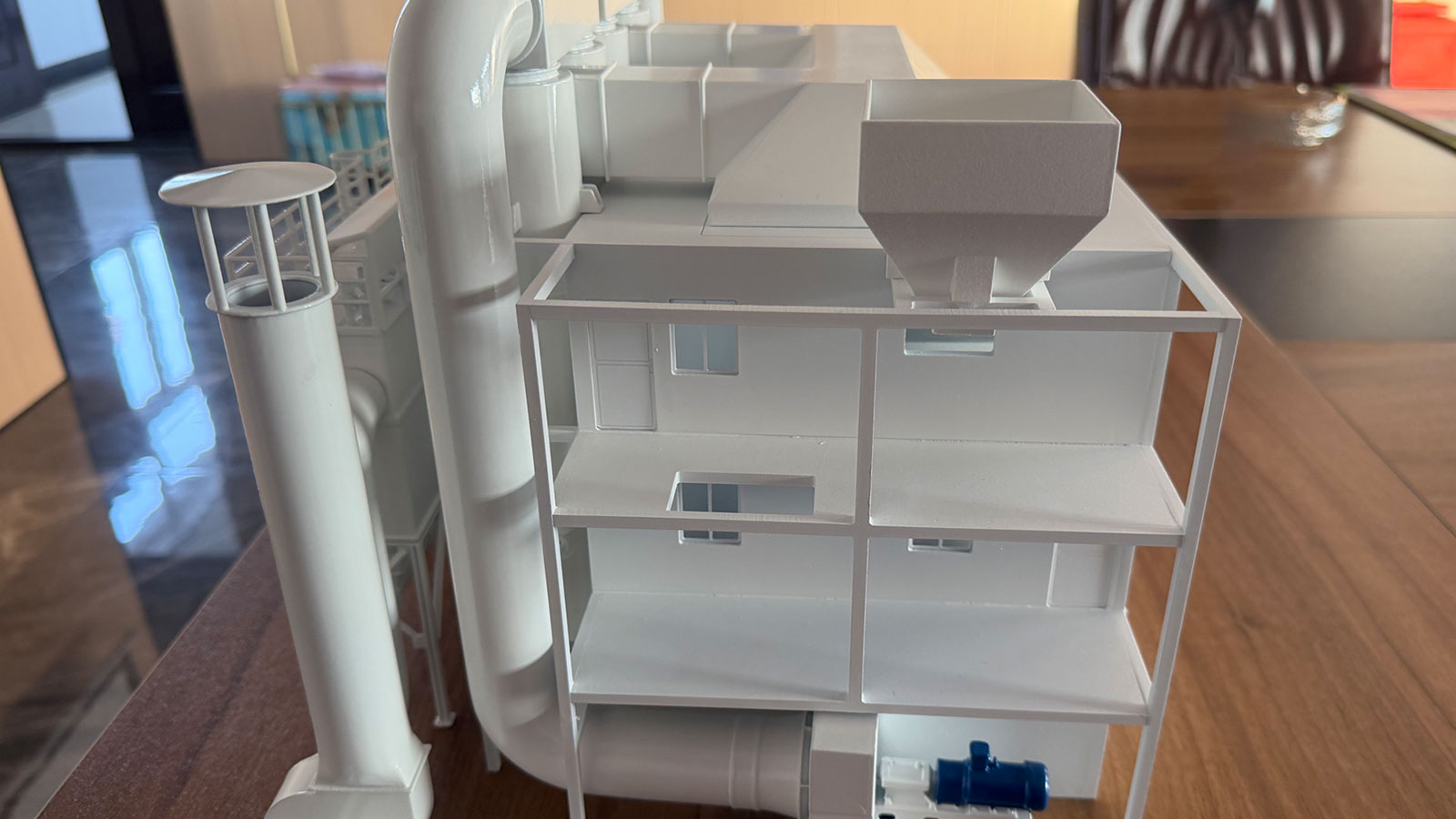

The KQT-C Dry-Process Jig is built with industrial durability in mind, designed to withstand the rigorous demands of coal mining operations. The primary components of the jig include a vibrating separation bed, an air pulsation system, and a control interface. The vibrating bed is made from high-quality, wear-resistant steel to ensure that it can handle the abrasive nature of coal particles over extended periods of operation.

The air pulsation system, powered by energy-efficient compressors, generates precise, high-frequency pulses that drive the separation process. The system’s adjustable settings allow for fine-tuning of the air flow and vibration intensity, ensuring optimal performance under varying feedstock conditions. Additionally, the integrated control interface allows for real-time monitoring, enabling operators to make adjustments to improve performance and maintain consistent separation efficiency.

Manufacturing processes focus on the use of durable materials and precision engineering to ensure the longevity and effectiveness of the equipment. Regular maintenance of components such as the air system, vibrating bed, and control systems is essential to maintaining high operational performance and minimizing downtime.

Factors Affecting Quality and Performance

Several factors can influence the quality and performance of the KQT-C Dry-Process Jig. The feedstock’s particle size distribution is one of the most important factors, as excessively coarse or fine materials can lead to inefficient separation. For optimal performance, feedstock should be ground to a consistent size to facilitate effective stratification.

Moisture content is another crucial variable. High moisture levels can negatively affect the separation process, leading to inefficient stratification and reduced recovery rates. Therefore, the dry-process technology is most effective when processing dry or low-moisture coal and other minerals.

Other factors, such as material shape and density variations, can also impact performance. For instance, irregularly shaped particles may not separate as efficiently, requiring further adjustment to air and vibration parameters. Regular calibration and monitoring are essential for maintaining optimal performance and ensuring that the jig operates within its desired efficiency range.

Supply Chain and Vendor Selection Criteria

When selecting a supplier for dry-process mineral separation equipment like the KQT-C Jig, companies should prioritize vendors with a proven track record in mining equipment manufacturing and a reputation for reliability. Key selection criteria include the supplier’s experience in delivering similar technologies, the availability of robust after-sales support, and the quality of materials used in the equipment’s construction.

In addition to the quality of the product, it is crucial to evaluate the supplier’s customer service capabilities. A supplier that offers comprehensive technical support, including installation, training, and maintenance, can help ensure that the equipment operates smoothly and that any issues are addressed quickly. Furthermore, the availability of spare parts and accessories, along with a reliable supply chain, can help minimize downtime and ensure the continued effectiveness of the equipment.

Common Industry Challenges and Pain Points

One of the most significant challenges in the coal processing industry is the increasing pressure to reduce water consumption and manage wastewater. Wet separation methods, while effective, are not sustainable in areas facing water scarcity or stringent environmental regulations. Additionally, these methods often result in high operational costs due to the need for water treatment and disposal.

Another challenge is maintaining consistent coal quality in the face of variable feedstock. Traditional methods may struggle to effectively process feedstocks with inconsistent moisture levels, particle sizes, or impurities. The KQT-C Dry-Process Jig addresses this issue by offering a high degree of flexibility, allowing operators to adjust air and vibration settings to accommodate varying feedstock conditions and improve coal purity.

Applications and Industry Use Cases

The KQT-C Dry-Process Mineral Separation Jig is particularly suited for use in regions with limited water availability, where dry processing technologies are a necessity. It has been successfully implemented in coal processing operations across the globe, where it has helped improve recovery rates, reduce operational costs, and minimize environmental impact.

In one notable example, a coal mining operation in Australia replaced its traditional wet separation system with the KQT-C Jig. The result was a 30% reduction in water usage and a 20% increase in coal recovery, leading to significant cost savings and improved operational efficiency.

Current Trends and Future Directions

The future of coal processing is increasingly focused on sustainability and efficiency. Dry-process separation technologies like the KQT-C Jig align with this trend by providing an environmentally friendly, cost-effective solution for coal recovery. The demand for these technologies is expected to grow as more mining operations look for ways to reduce their water footprint and comply with stricter environmental regulations.

Looking ahead, advancements in automation, sensor-based monitoring, and data analytics are likely to play a significant role in enhancing the efficiency of dry separation technologies. By integrating smart control systems and predictive analytics, mining operations can further optimize the separation process, improve product quality, and reduce energy consumption.

Frequently Asked Questions

What is the primary advantage of dry-process separation over traditional wet methods?

Dry-process separation eliminates the need for water, reducing both environmental impact and operational costs, while maintaining high efficiency in coal recovery.

Can the KQT-C Jig process materials other than coal?

Yes, the KQT-C Jig can be used to process other minerals with similar density differences, including industrial ores and non-ferrous minerals.

How does moisture content affect the performance of the KQT-C Jig?

High moisture content can reduce the jig’s efficiency by affecting the stratification process. Dry or low-moisture materials are ideal for optimal performance.

Is maintenance required for the KQT-C Jig?

Regular maintenance, including inspection of the vibrating bed and air system, is necessary to ensure consistent performance and minimize downtime.

Conclusion

The KQT-C Dry-Process Mineral Separation Jig represents a significant advancement in coal processing technology, offering mining operations a sustainable and efficient alternative to traditional wet separation methods. By leveraging air-based separation, the KQT-C Jig reduces water usage, improves recovery rates, and helps meet the growing demand for environmentally responsible mining practices. As the industry continues to evolve, technologies like the KQT-C Jig will play a pivotal role in shaping the future of coal and mineral processing.

Whatsapp

Whatsapp Điện thoại

Điện thoại

Bình luận

(0)